ONE STOP WIRE HARNESS ASSEMBLY SERVICE

Increase your application’s performance and productivity with Our cable & wire harness manufacturing expertise. Explore Solder Electronics Assembly for your Wire & Cable harness Harness Manufacturing Services.

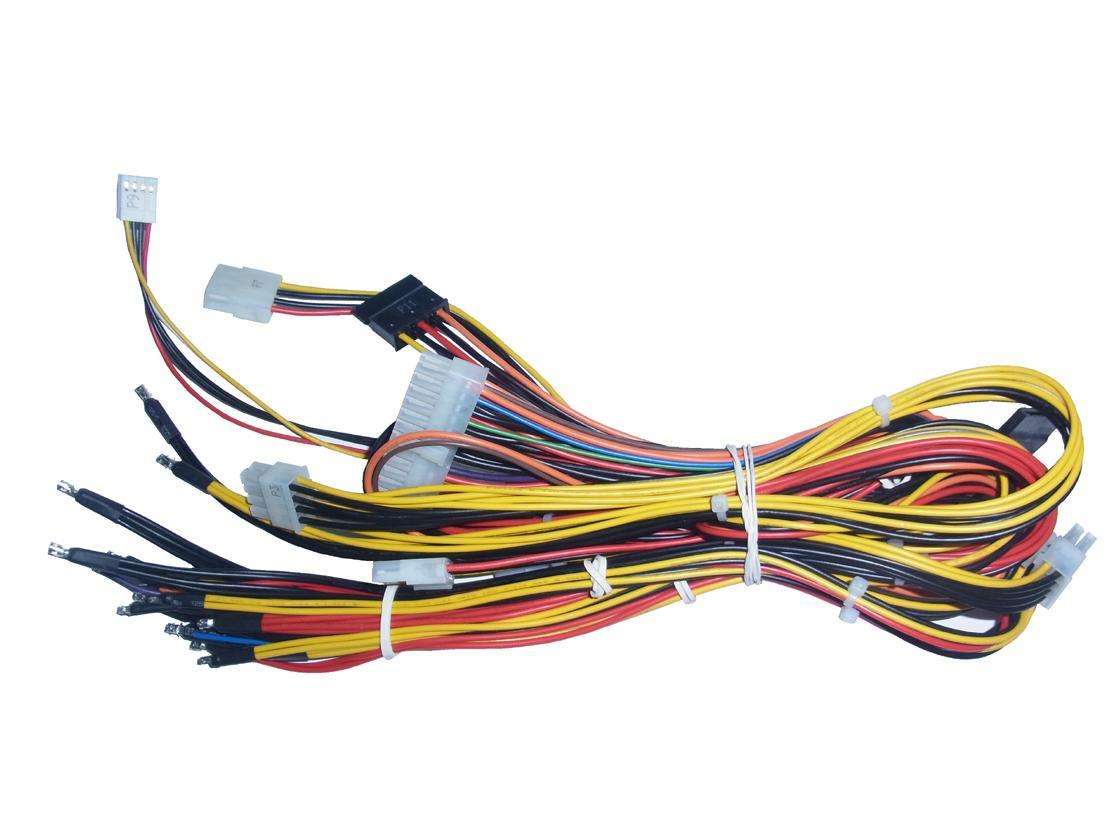

Wire Harness Assembly

Wire Harness Assembly play a major role in electronics product reliability. Process for stripping wires and cables and attaching connectors need to ensure strong connections. The appropriate strain relief technique prevents damage to the connection during normal use and helps ensure that your product has a long life in the field.

Our manufacturing team reviews your wire Assembly or cable assembly design and offers suggestions for manufacturability.

Solder Electronics Assembly manufacturing platform provides Cost-effective Cable Assemblies and Wire harness Manufacturing solutions for prototypes, NPI, Low-Mid volume manufacturing with the Highest Quality and on-time delivery.

Cable & Wire Harness PCB manufacturing services are supported with both turnkey and consignment basis mode to produce superior wire harness assembly built to customer’s specifications and expectations.

Cable & Wire Harness Manufacturing capability includes wire harnesses in a variety of lengths, wire gauges, and colors with multi-stage QC process and testing ensuring consistent quality and high production yield. Test Engineering includes the Development of Customer-specific Test jig and PCBA Test Fixtures.

Wire Harness Assembly

- Sophisticated Wire Assembly.

- Custom Cable & Wire Harness Manufacturer.

Types: –

- Multi-Conductor Cable Applications.

- Flat Cable, Multi wire Cable Harness.

- Chassis Wiring and Assembly.

- RF Broadband Cables.

- EMI Shielded Cable Harness.

- Semi-Rigid and Semi-flexible Cables.

- Coaxial Cables, Power Cable, Ribbon Cable.

- Airborne & Military Looms.

- Assembly with Standard, D-Sub, Mil-Spec, D-38999 Circular Connectors.